Pre-assembled Furnaces Land and Sea Transport

Seafastening design and heavy-load transport

Dextra Transport and Industry has been awarded for CRISP Package C which include the transport of modular furnaces and auxiliaries.

- Land Transport and Load-out at POL,

- Sea Transport on SPV deck carrier:

- From POL – Sattahip, Thailand.

- To POD – Jurong Island, Singapore

- Design, Supply, Fabrication and Installation of seafastening.

- Supervision of operations at POL and POD

Timeline

Purchase order

Engineering

Seafastening Fabrication

Shipments

8 days load-out & 6 days load-in for the 2nd shipment

DNVGL Hydraulic Trailer Stability and Sea Transport

ENGINEERING

Dextra Engineering scope of work included the design of the grillages, fasteners and bracing pin/pin connection. The strength verification of the SPV deck under the sea transport loads was checked as well by Dextra.

Land transport drawings and calculations were carried as per DNVGL Stability Criteria for the furnaces and stacks. Mooring and ballasting calculations, stowage plan, vessel stability were implemented for each shipment

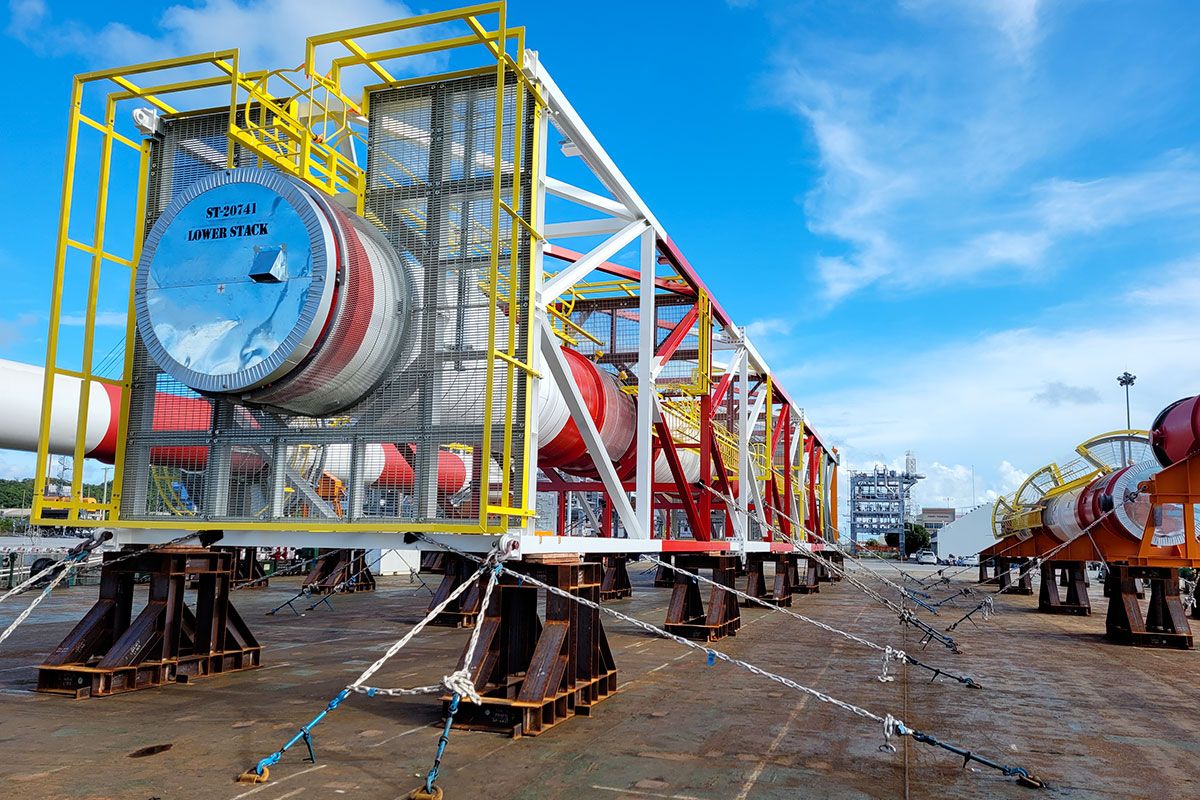

SEAFASTENING

The 190mT of steel were fabricated in two months and a half to meet the tight shipment schedule.

The high strength pins were fabricated and tested by Dextra Manufacturing.

All bracings were trial fit on the furnaces at the fabrication yard. This operation led by Dextra allowed to identify and fix clash before vessel arrival. After load-out, the long and short bracings were installed on the vessel using rough terrain crane and hoist rigging by our team. All these operations were done in hidden time to avoid demurrage.

LOAD OUT

All the furnaces and equipment were directly transported from fabrication yard to the SPV using SPMT. The cargoes were loaded out on the SPV using a 12m ramps to ensure that the ground pressure on the quayside remains within the allowable limits. One furnace or two stacks were loaded each day in seamless operations.

After SPMT jacked down the furnace on grillage, our team installed the bracings while welding the column fasteners and pad eyes to the grillages. These operations took place day and night. On shipment 2, Dextra managed to install 12 long bracings in less than 10 hours. 40 welders and fitters were mobilized during the shipments. MPI tests were done to verify the quality of welding before vessel sailed away.

Once stacks and loose items were set down on the 1.5m stools by the SPMT, the cargoes were secured to the deck by a total of 650m of soft chains. The soft chains were tensioned on the deck by the mean of welded d-rings and turnbuckles. This methodology allowed to safely secure the cargo in a record time.

DISCHARGING

The voyage from Sattahip to Singapore took 4 days. After berthing in Singapore, our team started to remove the lashing and hard seafastening to release the cargoes as soon as possible. Once stacks and furnaces were loaded-in, Dextra performed the vessel deck cleaning before departure of the vessel.