Oversized Power Plant Equipment on Public Road

Hydraulic Trailer and Gantry Crane

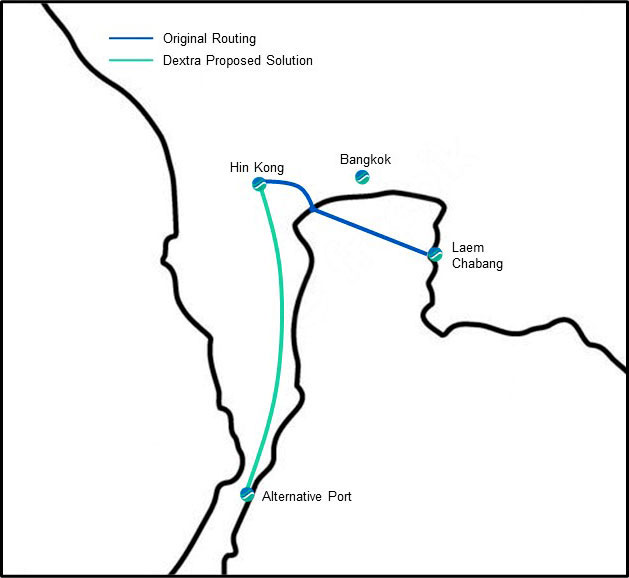

To construct the two units of HRSG (Heat Recovery Steam Generator) located at Hin Kong new combined cycle power plant, isolated 100km east Bangkok, the EPCI project contractor Mitsubishi Power through his Korean HRSG manufacturer BHI requested the transport of the 36 HRSG modules to be done as follows:

Thanks to its local market knowledge, Dextra Transport was not afraid to be the only bidder proposing an inland transport solution out of the request for quotation.

Original Routing:

- Offloading of the modules in Laem Chabang Port leading to high-cost storage at the port.

- Tandem lift to load and unload the modules with heavy duty cranes at the port on specialized river barges,

- Tides and flooding dependent river barge transport to the site,

- Construction of a roro jetty and dedicated storage area around 15kms to job site to offload and store the cargoes before delivery to site.

Dextra Proposed Solutions:

Which was using a port fully accessible by road located at around 322kms from the job site, saving tremendous amount of cost, transshipments, and risk to the customer.

Timeline

Solutions provided by Dextra Transport

Start of the road civil works

First Shipment

Second Shipment

Road extensions and Delivery Schedule

This “think out of box” and creative mindset combined with a strong technical background led to the award of the inland transport of all the OOG equipment required to erect the two HRSG units on site. This included the transport of 36 HRSG modules weighing up to 295 metric tons and measuring more than 30m long on 322 kilometers of public roads.

Our team did not stop here to propose the best solution. As the land transport of heavy lift has negative impact on local communities such as traffic jams, noises, and safety concerns, we proposed and constructed a 2 kilometers road through fields to reduce as much as possible the disturbance near the Hin Kong Power Plant.

This idea was positively received by the plant owner and communities.

The key for successful execution was then to put in place a delivery plan with close coordination with the authorities that would match the strict requirement from Mitsubishi Power: direct delivery from port to under the job site crane for installation of the module on foundation at site.

Challenges: Oversize Load Night Convoy

- In-house road survey, land transport drawings and supervision of the convoy operations.

- 13 major civil works spread over three different provinces to be engineered, managed with local authorities, and completed before arrival of the vessel,

- 3 nights inland transport with one convoy leaving every day from the port,

- High standards of Mitsubishi Power met by our team,

- Use of gantry crane to change configuration from single line to side by side at port, to avoid having two heavy duty cranes full time at the port reducing significantly handling cost,

- The job site was extremely congested with many simultaneous operations. Our team drawn in advance the trailer simulations to have the easiest and safest maneuvers at the job site. Our field supervisors were on site to ensure that all operations were going smoothly.